NEWS: JF Taylor Acquires Bugeye Technologies

JF Taylor Expands Solutions Offering with Acquisition of Specialized DoD Solutions Provider, Bugeye Technologies

Great Mills, MD – [April 7, 2025]

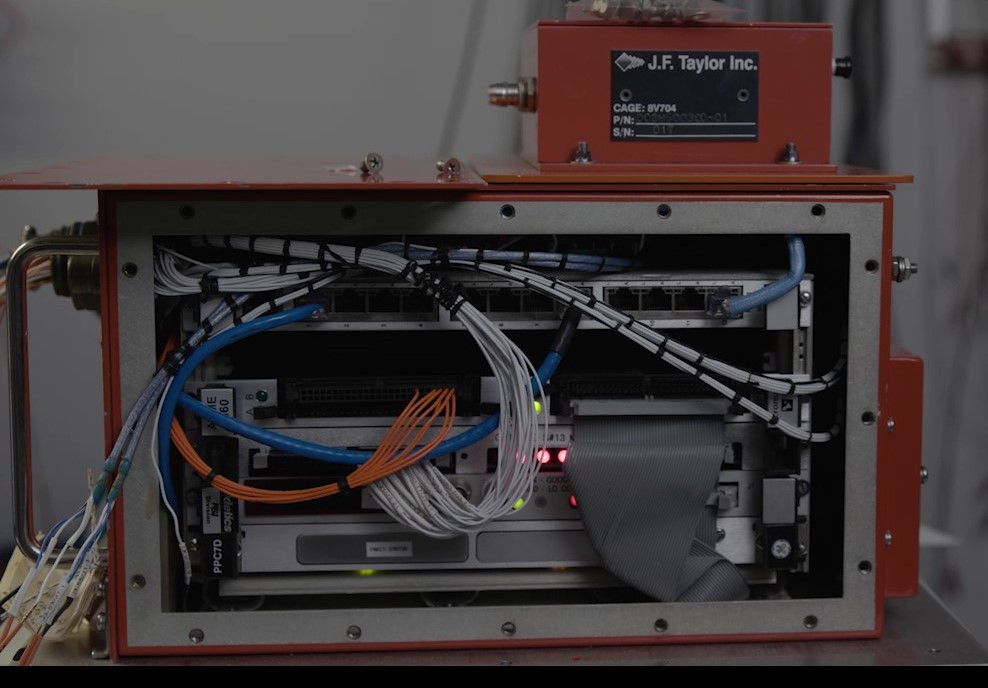

– JF Taylor Inc. announced today the acquisition of Bugeye Technologies Inc. (Bugeye), an engineering and manufacturing solutions company located in Union, Missouri. Bugeye specializes in high quality simulated hardware and custom electro-mechanical assemblies for aviation and simulation/training applications. This strategic alignment strengthens JF Taylor’s position as a leading small-business provider of cutting-edge training systems and defense solutions for the U.S. Department of Defense (DoD) and its international partners.

"We are excited to welcome Bugeye and its talented team to the JF Taylor family," said Chris Wasniak, JF Taylor chief operating officer. "Bugeye's proven performance in developing and delivering on-time, high-quality, and best-value solutions aligns perfectly with JF Taylor’s mission to provide our customers with the most advanced, comprehensive, and cost-effective readiness capabilities. This acquisition broadens our portfolio, increases our capacity, and positions us to better serve the needs of our customers in the rapidly evolving modern age."

Bugeye brings more than 22 years of experience in the defense industry as a supplier of realistic, serviceable and affordable products in the flight simulation industry. They design, engineer, and manufacture a variety of cockpits, control sticks, throttles, cyclics, collectives, yokes, rudder pedals and control loading at multiple levels of fidelity, from desktop to full mission trainers. They support more than 20 platforms that range from rotary wing aircraft including AH-64, H-60, and H-47, to fixed wing aircraft with F-16, F-22, F-35, and many more air and ground platforms.

"Joining forces with JF Taylor presents an incredible opportunity to leverage our combined expertise and resources to make an even greater impact on our customers’ mission success," said Kyle Zick, Bugeye president. "We are enthusiastic that this partnership will enable us to deliver even more innovative and effective solutions while expanding our capacity and capabilities."

The acquisition of Bugeye underscores JF Taylor’s commitment to investing in continuous capabilities enhancement to ultimately provide customers with a comprehensive suite of training and mission support solutions. By integrating Bugeye’s design and manufacturing capabilities with its existing expertise in highly complex military systems, JF Taylor will be able to offer a wider range of solutions that addresses the full spectrum of the warfighter’s training and operational needs.

About JF Taylor, Inc.

JF Taylor is a prominent DoD solutions provider, specializing in the development and delivery of advanced mission and training systems and solutions. With more than 40 years of experience as a design, engineering, and manufacturing company, JF Taylor delivers quality products and services to keep our military strong and our warfighters safe. Headquartered in Great Mills, Maryland, with a flagship office in Beavercreek, Ohio, JF Taylor is dedicated to supporting the critical needs of US military personnel and its foreign partners. JF Taylor strives to remain at the forefront of the military readiness and operational landscape, ensuring its customers have access to the most effective and efficient solutions available.

https://www.jfti.com/

About Bugeye Technologies

Established in 2003, Bugeye Technologies is the supplier of choice for industry and government organizations needing complex mechanical and electrical assemblies, design and build services, and commercially available simulation products. Located just outside St Louis, Missouri, their turnkey engineering, assembly, and final inspection support of Commercial-Off-the-Shelf flight simulation and custom-fabricated assemblies enable deliveries throughout the U.S. and worldwide.

https://www.bugeyetech.com/

Media Contact: Sandi Hauenstein |

sahauenstein@jfti.com

| (301) 862-3939

.jpg)